How to make FFU Fan Filter Unit save electricity costs? This is a big question for pharmaceutical and electronics factories when the FFU system operates continuously 24/7 and consumes more than 50% of HVAC electricity. This article will share 5 solutions to help optimize FFU operation while still ensuring the cleanliness level meets GMP, ISO 14644

In cleanroom areas, Fan Filter Unit (FFU) systems account for a large part of operating costs due to continuous operation and high performance requirements. So how does FFU save electricity costs while still ensuring a clean environment according to standards? This article will guide you from choosing the right components, intelligent control to operating procedures - to optimize electricity costs and extend equipment life.

1. Common Issues When Using FFUs

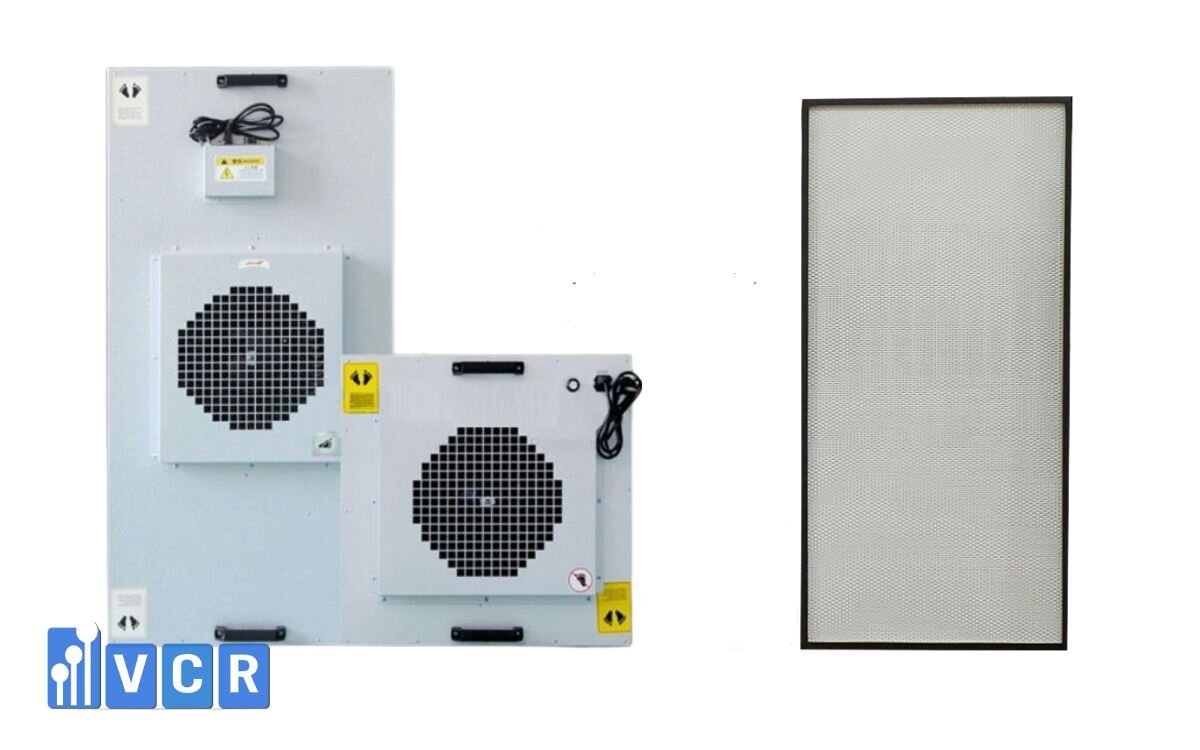

Fan Filter Units (FFUs) are among the most critical components in a cleanroom system, especially in high cleanliness zones such as weighing rooms, filling areas, or packaging lines.

However, due to their continuous 24/7 operation and the typically large number of units installed (sometimes hundreds in a single factory), FFUs are a major contributor to high energy consumption.

According to real-world data from pharmaceutical plants certified to EU-GMP or ISO 14644 standards, FFUs can account for 30% to 60% of total HVAC/cleanroom electricity consumption-exceeding that of central air conditioners or AHUs.

Some common causes of excessive power consumption include:

- Improper layout planning, leading to excessive airflow and energy waste.

- Use of traditional FFUs with high-power AC motors.

- No speed control system, causing FFUs to constantly run at maximum capacity.

- Dirty or clogged filters that require fans to operate harder to maintain airflow.

The result is skyrocketing operational costs, reduced equipment lifespan, and increased strain on the central HVAC system.

So how can you reduce FFU energy consumption without compromising cleanroom standards like GMP or ISO? → The following section presents five proven optimization methods successfully applied by many factories.

See more: How to check the wind speed of FFU in ISO clean room

2. Five Ways to Reduce FFU Energy Consumption

To reduce operational costs while maintaining filtration performance and cleanroom compliance, businesses can adopt one or more of the following strategies:

1. Choose FFUs with EC Motors Instead of AC

EC (Electronically Commutated) motors are an advanced alternative to traditional AC motors. Integrated with smart control chips, EC motors allow precise and flexible speed control.

- Save 30-50% energy compared to AC motors of equivalent capacity.

- Quieter operation, less heat generation, and longer lifespan.

- Capable of adjusting fan speed based on demand, reducing unnecessary energy use.

This is the optimal choice for 24/7 operations in pharmaceutical or electronics facilities seeking to control energy costs.

2. BMS system integration

By combining FFUs with pressure sensors and VFDs, the system can automatically regulate airflow based on real-time cleanroom conditions.

- Reduces fan speed when pressure reaches the target level, saving energy.

- Increases speed when pressure drops or when human/equipment activity rises.

Automation is especially beneficial for shift-based production or areas with fluctuating load requirements.

3. Optimize FFU Placement Based on Cleanroom Design

The number and layout of FFUs should be based on the required cleanliness level and operational goals-more is not always better.

- ISO 5 or filling zones may require high-density FFUs (90-100% ceiling coverage).

- ISO 7 or changing rooms may only need partial coverage (30-60%) to conserve energy.

Over-installing FFUs not only wastes energy but also increases investment and maintenance costs.

4. Use Intermittent Operation Mode When Applicable

Not all cleanroom zones require continuous 24/7 FFU operation.

- Support zones like airlocks or clean corridors can be set to operate on a schedule or via occupancy sensors.

- Some factories have cut 20-30% of their FFU electricity costs just by scheduling operation based on production shifts.

Note: Always assess the impact on cleanliness level before applying this strategy.

5. Perform Regular Maintenance and Replace Filters on Time

Clogged prefilters or HEPA filters force FFUfans to work harder, leading to increased power consumption.

- Prefilters should be cleaned or replaced every 3-6 months.

- HEPA filters should be checked and replaced every 12-24 months, depending on usage.

Also, regularly inspect fan noise and vibration-these are indicators of inefficient motor operation.

See more:Can FFU (Fan Filter Unit) Be Connected to an Air Duct?

3. Power Consumption Comparison Between FFU Types

Not all FFUs consume the same amount of electricity. Choosing the right FFU based on your application can significantly reduce annual operating costs.

Here is a comparison of three common types of FFUs:

|

FFU Type |

Motor Type |

Average Power Consumption |

Key Features |

|

Traditional FFU |

AC motor |

180-220W |

Low cost, simple design, high power consumption |

|

Energy-saving FFU |

EC motor |

90-120W |

Reduces power by 40-50%, durable, quiet operation |

|

Smart FFU |

EC + pressure sensor |

70-100W |

Automatically adjusts airflow based on load, maximizes savings |

Conclusion:

- AC FFUs are suitable for low-budget cleanrooms with limited airflow control needs.

- EC FFUs offer a balanced investment-return ratio with long-term savings.

- Smart FFUs are ideal for GMP/ISO-certified facilities requiring consistent performance, energy efficiency, and flexible operation.

Investing in energy-saving FFUs not only reduces monthly electricity bills but also extends HVAC system lifespan, reduces central AC load, and supports long-term sustainable operations.

4. Recommendations for Energy-Efficient FFUs by Industry

Each industry has different cleanroom requirements in terms of cleanliness class, operating frequency, and environmental conditions. Selecting the appropriate FFU helps meet standards (GMP, ISO, HACCP, etc.) while optimizing energy costs over time.

|

Industry |

Cleanroom Characteristics |

Recommended FFU Type |

|

Pharmaceuticals |

ISO 7 - ISO 5, 24/7 operation, high stability |

EC FFU with pressure sensor - maintains constant pressure, adjusts automatically |

|

Electronics |

ISO 5, high electrostatic control |

EC FFU with ionizer - reduces power usage, effective ESD control |

|

Cosmetics |

ISO 7 - ISO 8, shift-based production |

Standard EC FFU - more efficient than AC, fits variable schedules |

|

Food |

ISO 8 - HACCP, basic cleanroom setup |

Basic FFU (AC/EC with intermittent mode) - programmable schedule, energy-saving |

Additional Suggestions:

- In pharmaceutical environments, choose FFUs capable of integrating with SCADA systems to monitor energy usage and operational status.

- In cosmetics and food industries, consider occupancy sensor-based controls to turn off FFUs when no personnel are present, saving up to 20-25% on energy.

Depending on the industry, initial investment in EC or smart FFUs may be higher, but the payback period is typically only 6-12 months due to significant electricity savings.

See more: Laminar Airflow Cleanroom Control in FFUs

5. Frequently Asked Questions

1. Do EC FFUs really save energy?

Yes. In real factory conditions, FFUs with EC motors can cut electricity consumption by 40-50% compared to AC motors. They also operate more quietly and have a longer lifespan.

2. Can FFUs operate intermittently?

It depends on the area and production process. In spaces that do not require continuous ISO-class maintenance (e.g., clean corridors, airlocks, or support zones), FFUs can be scheduled to run only during required periods.

3. How should FFUs be maintained to reduce power use?

Routine maintenance helps lower energy usage:

- Clean prefilters monthly to prevent clogging.

- Replace HEPA filters every 12-24 months depending on usage.

- Monitor noise, vibration, and airflow to ensure fan motors are not overworked.

4. Does installing fewer FFUs affect cleanroom quality?

Yes. Insufficient clean airflow can reduce dust filtration efficiency, disrupt pressure balance, and fail ISO standards. FFU density must be calculated based on target cleanliness class and airflow requirements-cutting corners may compromise quality.

6. Want to Optimize Your FFU Energy Costs?

Choosing the right type of FFU and configuration can help your business save millions of VND monthly while maintaining strict GMP/ISO compliance.

VCR offers:

- Optimal FFU layout design consultation

- Selection of energy-efficient EC FFUs

- GMP-compliant equipment with long-term warranty

Contact us now for a free consultation:

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Diep VCR