FFU is an important air filtration device that helps maintain clean air flow in clean rooms. However, if installed incorrectly, FFU can cause pressure imbalance, reduce filtration efficiency and generate air turbulence. This article will help you identify and promptly handle errors so that the system operates stably and meets ISO/GMP standards.

- 1. What is an FFU and why is proper installation important?

- 2. Mistake 1: Incorrect airflow direction during FFU installation

- 3. Mistake 2: Uneven installation causes FFU misalignment

- 4. Mistake 3: Failing to check FFU sealing after installation

- 5. Mistake 4: FFU not integrated with the central control system

- 6. Mistake 5: Lack of routine maintenance after FFU installation

- 7. Quick Q&A on FFU installation and operation

- 8. Need help installing or selecting the right FFU?

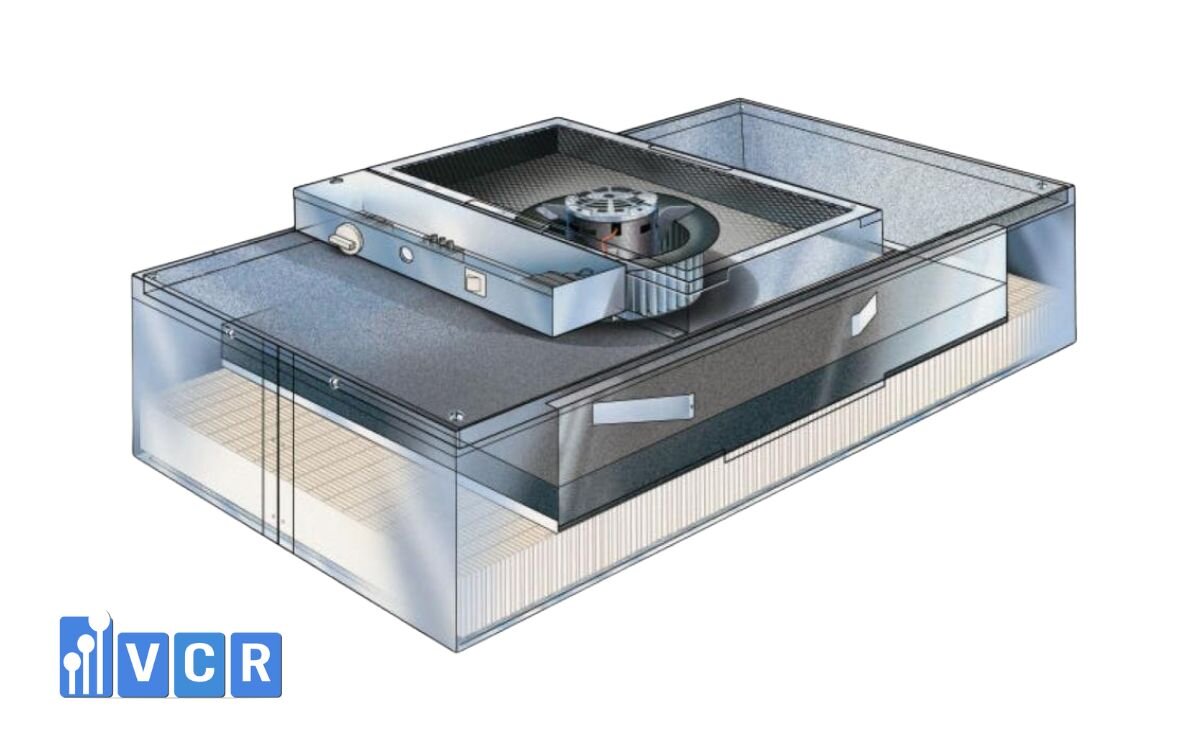

1. What is an FFU and why is proper installation important?

A Fan Filter Unit (FFU) is a device that integrates a fan and HEPA/ULPA filter, responsible for generating clean, stable, unidirectional airflow into the cleanroom workspace. FFUs are typically installed directly on the ceiling of a cleanroom or within mini clean booths.

In practice, many issues related to air quality and room pressure in cleanrooms are not caused by product defects, but rather by improper installation. Below are common mistakes when installing FFUs and specific solutions to help you maintain optimal filtration performance.

2. Mistake 1: Incorrect airflow direction during FFU installation

Symptoms:

After installation, you may notice that the airflow does not descend directly as expected. Instead, it creates turbulence or even pushes dust back toward the working area. This is a clear sign that the FFU has been installed in reverse airflow orientation.

Main cause:

This issue usually occurs when the installer cannot clearly identify the air intake and outlet of the FFU. Many FFU models are designed with symmetrical housings, making it easy to confuse the airflow direction without clear instructions.

How to fix:

- Carefully read the airflow schematic provided by the manufacturer before installation - often printed on the FFU body or in the technical documentation.

- During transport and pre-installation, clearly label the “intake” and “outlet” ends using color-coded tags to prevent confusion.

- After installation, perform a quick smoke test to ensure airflow moves correctly downward from the FFU.

See more: Supplier of FFU - Fan Filter Unit meeting GMP standards in Vietnam

3. Mistake 2: Uneven installation causes FFU misalignment

Symptoms:

During operation, if you notice inconsistent airflow across the cleanroom or unstable pressure between zones, the likely cause is an unbalanced or tilted FFU.

Main causes:

- Ceiling suspension is uneven due to inaccurate installation or lack of proper leveling tools.

- The mounting screws are tightened unevenly, causing the frame to tilt and leading to fan misalignment and airflow disruption.

How to fix:

- Before securing the FFU to the ceiling, use a laser level to ensure a perfectly horizontal plane.

- Use specialized mounting frames with fine adjustment points to enable quick and precise leveling, even after partial installation.

- After mounting, verify airflow uniformity with an anemometer at multiple points.

Note: A tilted FFU not only reduces filtration efficiency but may also damage the motor due to unbalanced mechanical stress.

4. Mistake 3: Failing to check FFU sealing after installation

Symptoms:

Even when the FFU appears to operate normally, if you detect fine dust entering the clean zone or observe abnormal pressure fluctuations, the issue likely lies in poor sealing at the FFU mounting point.

Main causes:

- Misaligned or improperly fitted gaskets, or use of incorrect gasket size/material.

- Installation was rushed, skipping proper inspection of contact surfaces between FFU and the ceiling or mounting frame.

How to fix:

- Conduct a leak test immediately after installation using one of the following methods:

- Smoke test: Observe smoke paths near the sealing line to detect any leaks.

- Light test: Shine a strong light from above the FFU and inspect from below for any visible light leaks.

- Only use gaskets compliant with ISO 14644 standards, preferably made of high-elasticity materials such as silicone foam or polyurethane (PU).

- If leaks are detected, uninstall and reinstall the FFU, ensuring even torque and level alignment during mounting.

See more: Latest price list of FFU Fan Filter Unit used in Cosmetic factory

5. Mistake 4: FFU not integrated with the central control system

Symptoms:

During operation, you cannot increase/decrease the FFU fan speed from the control room, or the HVAC system does not respond properly to changes made through the BMS. This indicates that the FFU is not compatible with the central control system.

Main causes:

- Standard FFU (On/Off version) is installed, while the system requires VFD control signals or BMS integration.

- Selected FFU model does not have digital communication ports such as Modbus RTU, RS485, or lacks remote control capabilities.

How to fix:

- At the design stage, clearly define control requirements:

- For basic On/Off control → standard FFU is sufficient.

- For speed adjustment → choose FFUs with built-in VFD or VFD compatibility.

- For BMS integration → ensure the FFU supports Modbus RTU, RS485, or TCP/IP.

- Carefully review the FFU datasheet before ordering to confirm compatibility with your control interface.

- If the wrong model is already installed, you may consider using an intermediary controller (converter) - although this increases cost and complexity.

Proper integration from the start can save significant costs on maintenance, adjustments, and production downtime.

6. Mistake 5: Lack of routine maintenance after FFU installation

Symptoms:

After several months of use, the FFU starts making loud noise, airflow decreases significantly, or the HEPA filter becomes clogged quickly. If not addressed promptly, this can severely impact room cleanliness and reduce the lifespan of the unit.

Main causes:

- No preventive maintenance plan was set up from the beginning.

- Pre-filter cleaning was skipped, causing dirt to accumulate quickly on the HEPA filter.

- No early warning system for high differential pressure conditions.

How to fix:

- Establish a routine FFU maintenance schedule, including:

- Clean the pre-filter monthly (depending on the environment).

- Replace HEPA filters every 6-12 months, or when differential pressure exceeds acceptable levels (typically 250-300 Pa).

- Integrate differential pressure sensors for each FFU or group of FFUs to trigger alerts when pressure increases, allowing timely filter replacement.

- Log operational data (pressure, noise, airflow) to monitor equipment condition over time.

A properly maintained FFU can operate reliably for 3-5 years without motor replacement - significantly reducing operational costs.

See more: Unveiling the Advantages of FFU Systems in Cleanrooms

7. Quick Q&A on FFU installation and operation

- Can FFUs be self-installed or do they require a specialist?

→ Self-installation is not recommended without experience.

Installing an FFU requires a clear understanding of airflow direction, ceiling suspension structure, sealing standards, and cleanroom pressure control. Therefore, it's best to involve HVAC technicians with experience in GMP or ISO 14644-compliant cleanroom environments to ensure optimal performance from the start. - When should the FFU system be rechecked after installation?

→ Rechecking should occur after 1-2 days of actual operation.

Once the FFU is running stably, basic tests such as pressure measurement, leak testing (smoke test), and airflow validation should be conducted to ensure correct installation and identify any potential issues. - Why does the FFU become noisy after a few months?

→ This is usually caused by motor wear or clogged filters.

When the HEPA filter is heavily clogged, the fan has to work harder to maintain airflow, which increases noise. Additionally, the motor may degrade if not properly maintained. The solution is to set a pre-filter cleaning and HEPA replacement schedule, and monitor differential pressure regularly for early issue detection.

8. Need help installing or selecting the right FFU?

Proper FFU installation not only ensures clean air quality but also extends equipment life and reduces operating costs for your facility.

If you are:

- Struggling with correct FFU installation

- Unsure which FFU model suits different cleanroom classes (ISO 5, 7, 8…)

- Looking for guidance on integrating FFUs with your building management system (BMS)

→ The VCR cleanroom technical team is ready to support you one-on-one, completely free of charge.

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Diep VCR