FFU – Fan Filter Unit is an air filtration device that integrates an exhaust fan and a high-performance HEPA/ULPA filter, providing clean air directly to the medical clean room. Unlike a central filtration system, FFU operates independently, is easy to install on the ceiling or wall, and helps to optimize sterile environment control.

- 1. What is an FFU Fan Filter Unit?

- 2. Advantages of FFU in Medical Cleanrooms

- 3. Latest Price List of FFU Fan Filter Unit for Medical Cleanrooms

- 4. How to Choose an FFU Fan Filter Unit for Medical Cleanrooms

- 5. Frequently Asked Questions about FFU Fan Filter Units

- 6. Contact for Quotation & FFU Installation Consultation

1. What is an FFU Fan Filter Unit?

Definition of FFU (Fan Filter Unit)

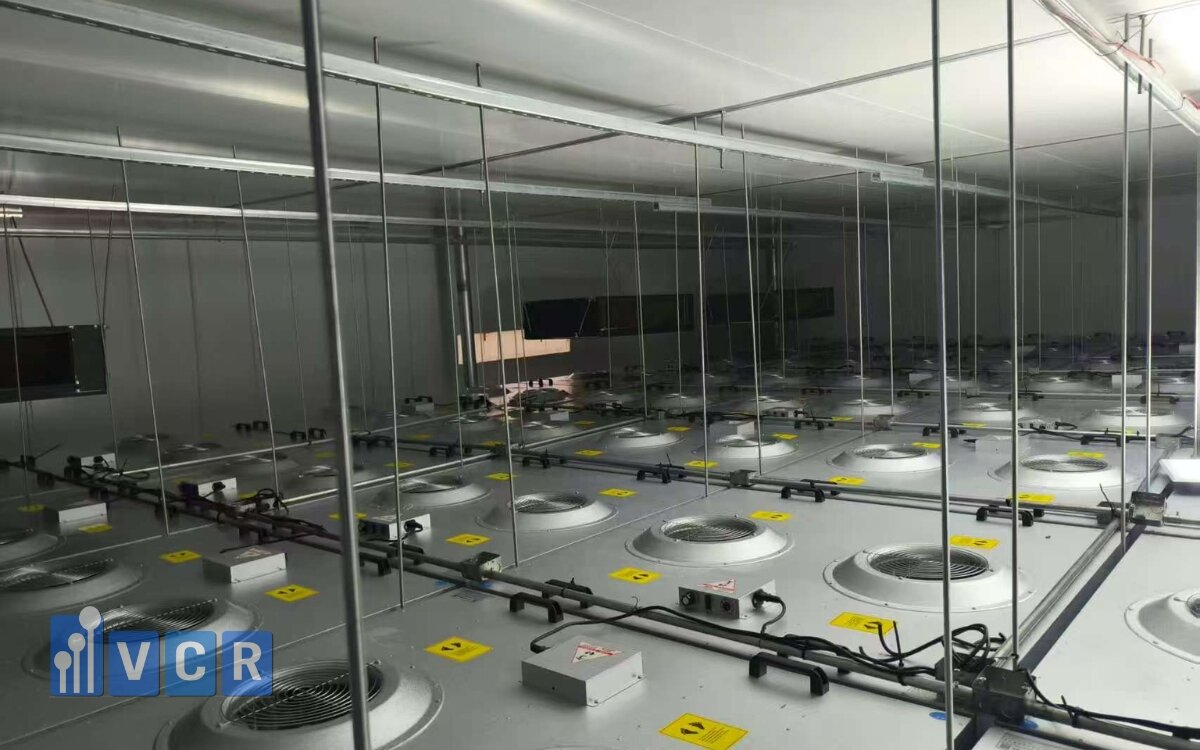

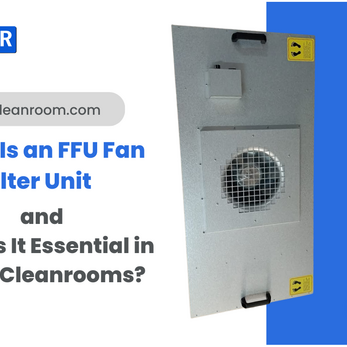

An FFU - Fan Filter Unit is an air filtration device that integrates a built-in fan and a high-efficiency filter, designed to supply clean airflow directly into cleanroom areas. Unlike centralized filtration systems, FFUs operate independently and can be flexibly installed on ceilings or walls, optimizing contamination control in sterile environments.

Basic Structure

A typical FFU consists of three main components:

- Fan: Creates suction pressure and pushes airflow through the filter.

- HEPA or ULPA filter: Removes fine dust, bacteria, and microscopic particles ≥ 0.3 microns with an efficiency of 99.97% or higher.

- Frame and housing: Commonly made from powder-coated steel, stainless steel, or aluminum to ensure durability and corrosion resistance.

Role in Medical Cleanrooms

In medical cleanrooms such as operating rooms, laboratories, microbiological culture areas, or sterilization zones, FFUs play a vital role in:

- Removing dust, bacteria, and harmful microorganisms from the air.

- Maintaining a stable cleanliness level in compliance with ISO 14644 or GMP standards.

- Preventing cross-contamination between different areas, ensuring the safety of both patients and healthcare staff.

An FFU can be considered the “heart” of a cleanroom system, determining the air quality and safety of critical medical operations.

2. Advantages of FFU in Medical Cleanrooms

High filtration efficiency

Equipped with HEPA or ULPA filters, FFUs can remove up to 99.97% of airborne particles ≥ 0.3 microns, and up to 99.999% with ULPA filters. This ensures that air inside medical cleanrooms remains pure, meeting the strict requirements of GMP and ISO 14644 standards.

Energy-saving and long lifespan

FFUs typically use high-efficiency motors that operate quietly and consume low power (around 150-250W). With optimized design and durable materials, the lifespan of an FFU can reach 5-7 years or more, reducing operating and maintenance costs for hospitals and laboratories.

Easy installation and maintenance

FFUs can be directly mounted on ceilings or integrated into modular ceiling systems, making them adaptable to different room layouts. For maintenance, users only need to remove the cover and replace the filter without affecting the entire system, saving both time and labor.

Optimal solution for specialized areas

With the ability to deliver a continuous flow of clean air, FFUs are the preferred choice for:

- Operating rooms: Maintaining a sterile environment and reducing the risk of post-surgical infections.

- Laboratories & microbiological culture rooms: Preventing contamination and ensuring accurate test results.

- Sterilization & pharmaceutical storage areas: Strictly controlling bacteria, fine dust, and harmful particles.

In short, an FFU is not just a regular air filtration device but a comprehensive solution that helps medical cleanrooms meet international standards, ensuring patient safety and supporting efficient healthcare operations.

See more: Unveiling the Advantages of FFU Systems in Cleanrooms

3. Latest Price List of FFU Fan Filter Unit for Medical Cleanrooms

Factors Affecting Price

- Size & airflow: Larger FFUs provide higher airflow and cost more. For example, a 4×4 ft FFU (~1175×1175 mm) is about 15-20% more expensive than a 2×4 ft unit.

- Filter type: HEPA (≥ 99.97% @ 0.3 micron) is cheaper; ULPA (≥ 99.9995%) is usually 20-40% more expensive.

- Housing material: Powder-coated steel is cost-effective; stainless steel 304 offers excellent corrosion resistance but costs 30-50% more.

- Upgraded features: EC motor for energy saving (+10-15%), anti-static finish (+5-10%), noise reduction design (+8-12%).

- Brand & certification: International brands (e.g., Nidec, Camfil) are 25-40% more expensive but provide higher durability; products certified to ISO, CE, RoHS also command higher prices.

- Quantity & additional costs: Bulk orders receive 5-15% discounts. Shipping and installation costs (especially for stainless steel units) usually account for 5-10% of total expenses.

Reference Price List 2025

|

Model |

Dimensions (mm) |

Filter type |

Housing |

Airflow (m³/h) |

Reference price (VND, excl. VAT & installation) |

|

FFU-24HEPA |

1175×575×300 |

HEPA |

Steel, coated |

~1,000 |

9,800,000 - 11,200,000 |

|

FFU-24ULPA |

1175×575×300 |

ULPA |

Steel, coated |

~1,000 |

12,500,000 - 14,000,000 |

|

FFU-34HEPA |

1175×875×300 |

HEPA |

Stainless steel 304 |

~1,500 |

11,800,000 - 13,200,000 |

|

FFU-34ULPA |

1175×875×300 |

ULPA |

Stainless steel 304 |

~1,500 |

14,500,000 - 16,000,000 |

|

FFU-44HEPA |

1175×1175×300 |

HEPA |

Stainless steel 304 |

~2,000 |

15,500,000 - 17,500,000 |

|

FFU-44ULPA |

1175×1175×300 |

ULPA |

Stainless steel 304 |

~2,000 |

18,000,000 - 20,500,000 |

Prices above exclude VAT and shipping. VCR can adjust according to technical specifications and order volume.

4. How to Choose an FFU Fan Filter Unit for Medical Cleanrooms

Identify the required cleanroom standard

In the healthcare sector, cleanrooms must comply with ISO 14644 and GMP. Before selecting FFUs, determine the cleanliness level (ISO Class 5, 6, 7, or 8) to define the number of units and filter type required.

Consider room area and airflow demand

Each FFU typically provides airflow of 1,000 - 2,000 m³/h. For a 30 m² operating room, 6-8 FFUs may be needed depending on the required cleanliness class. Calculating total airflow ensures sufficient clean air without waste.

Choose the filter type

- HEPA H13/H14: Suitable for most operating rooms and laboratories.

- ULPA U15/U16: Required for ultra-sterile areas, such as organ transplant rooms or cell culture laboratories.

Select suitable housing material

- Powder-coated steel: Cost-effective, suitable for most applications.

- Stainless steel 304: Highly durable, corrosion-resistant, ideal for harsh environments or where aesthetics are important.

Prioritize safety and energy-saving features

- EC motor for energy efficiency.

- Anti-static and noise-reduction design.

- Integrated pressure gauge or filter replacement alarm.

See more: Demystifying the Air Filtration Duo: FFU vs. HEPA Box

5. Frequently Asked Questions about FFU Fan Filter Units

How is an FFU different from a HEPA Box?

An FFU (Fan Filter Unit) integrates a fan and a filter to actively generate a clean airflow. A HEPA Box only contains the filter without a fan, so it depends on a central air system.

How often should an FFU filter be replaced?

Typically, the replacement cycle for HEPA/ULPA filters is 12-18 months, depending on usage intensity and ambient particle load. For ultra-sterile areas such as operating rooms, quarterly inspections are recommended to ensure air quality.

Is an FFU energy-efficient?

Yes. Modern FFUs often use EC motors or energy-saving fans, with power consumption around 150-250 W, reducing operating costs and heat load in the cleanroom.

Is an FFU suitable for Grade C or D cleanrooms?

Yes. FFUs are flexible for multiple cleanliness classes (ISO Class 5-8, GMP Grades A-D). For Grade C/D rooms, an appropriate number of FFUs and the right filter type will meet the requirements.

Are FFUs noisy during operation?

Typical sound levels are about 50-60 dB, comparable to normal conversation. Some premium models feature noise-reduction designs suitable for operating rooms or other noise-sensitive areas.

Can FFUs be customized?

Yes. Manufacturers can tailor dimensions, filter grade, housing materials, motor type, and noise performance to the specific design needs of each medical cleanroom.

See more: Understanding FFU's Impact on HEPA Filters

6. Contact for Quotation & FFU Installation Consultation

Don’t choose an FFU based on gut feeling—let VCR’s technical experts help you:

- Recommend configurations compliant with ISO 22716 / GMP.

- Prepare quotations based on dimensions, quantity, and project requirements.

- Provide technical drawings, HEPA testing certificates, and supplier qualification documents.

- Nationwide delivery, on-site installation, and periodic maintenance.

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Diep VCR