FFU – clean air filter is the ideal device for food processing factories, helping filter fine dust, microorganisms, and unpleasant odors. With a compact design, easy installation, and compliance with ISO and HACCP standards, FFU helps maintain a clean, safe environment in production. Summary

- 1. What is FFU? Why do food processing factories need it?

- 2. Selection criteria for FFU in food processing factories

- 3. Benefits of installing properly specified FFU in food factories

- 4. Reputable FFU supplier – key criteria to choose

- 5. VCR’s FFU – optimal solutions for the food industry

- 6. FAQ – Common FFU questions for food processing factories

1. What is FFU? Why do food processing factories need it?

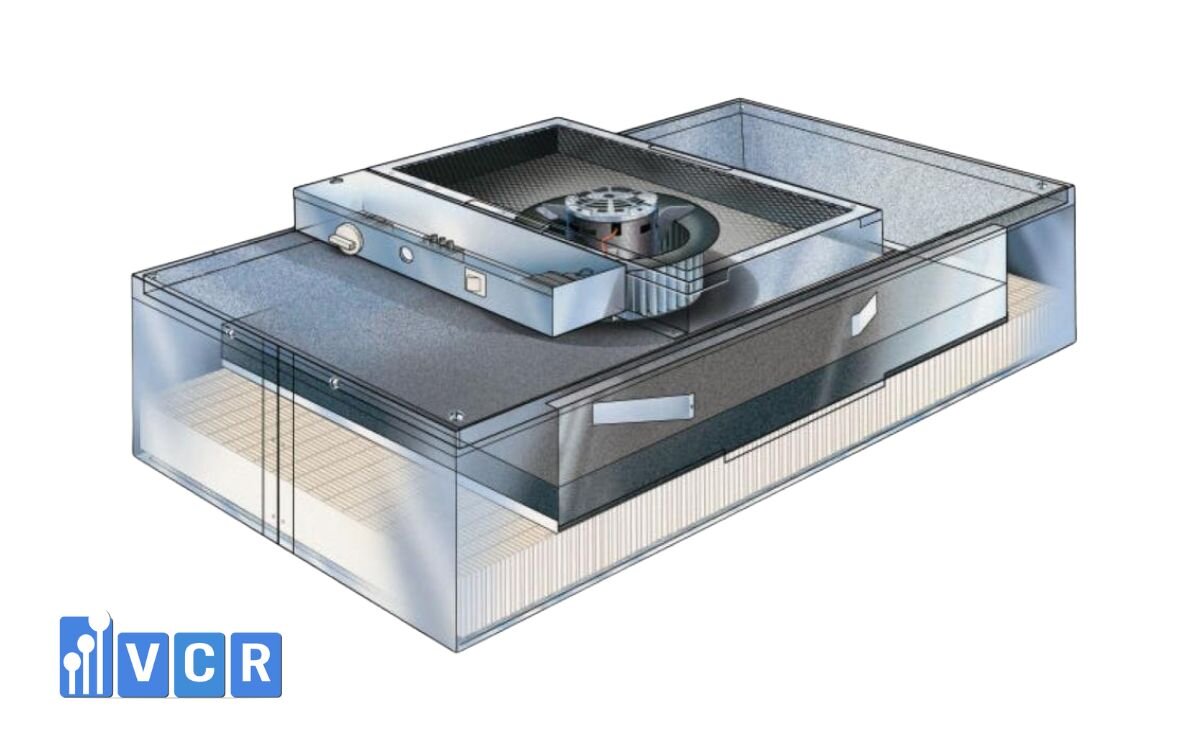

FFU (Fan Filter Unit) is an air purification device integrated with a fan. It draws air in from the top side and pushes cleaned air downward according to the laminar flow principle. This device is typically installed in the ceiling of clean rooms or in areas requiring high air quality control, such as food processing, pharmaceutical, or electronics zones.

Each FFU consists of three main components:

-

Fan: generates pressure to draw in and push air

-

HEPA or ULPA filter: removes dust particles, bacteria, and microorganisms

-

Corrosion-resistant casing: often made from electrostatically coated steel or stainless steel to suit humid environments

Why is FFU especially important for food processing factories?

The food industry requires very high standards of hygiene, safety, and microbial control. During production and packaging, if the air contains dust, bacteria or foreign odors, there is a serious risk of product spoilage, contamination, and food safety hazards. This not only affects product quality, but also endangers consumers’ health and the company’s reputation.

Installing an FFU system helps:

-

Filter fine dust, microorganisms, and unpleasant odors

-

Create food-industry clean rooms meeting ISO or HACCP standards

-

Control microbial contamination during production, reducing cross‑contamination risks

-

Maintain stable cleanliness in processing, packaging, or storage zones

Because FFUs can operate independently and integrate easily into clean-room ceiling systems, they become the optimal choice for food processing factories striving to raise cleanliness standards while complying with strict domestic and international food safety regulations.

Read more: Latest price list of FFU Fan Filter Unit used in food factory

2. Selection criteria for FFU in food processing factories

Choosing a clean-air device (FFU) for a food processing plant depends not only on price, but must suit technical standards and production characteristics. Key factors to consider include:

-

Cleanliness level compatible with each production area

Clean rooms in food factories are classified by cleanliness (Cleanroom Class), typically per ISO 14644‑1. Different zones require different cleanliness levels:-

Class 100–1000: suitable for final product packaging

-

Class 10,000–100,000: for raw material processing or storage areas

-

-

Filter type: HEPA or ULPA

-

HEPA (High Efficiency Particulate Air): filters 99.97% of particles ≥ 0.3 µm

-

ULPA (Ultra Low Penetration Air): filters up to 99.9995% of particles ≥ 0.12 µm

Depending on the nature of the product (fresh, frozen, or dry), choose a filter type that balances efficiency and maintenance cost.

-

-

Airflow, noise, and fan power

-

Airflow (CFM or m³/h): calculated based on room volume and air changes per hour (ACH)

-

Noise level (dB): should stay under ~60 dB to avoid disturbing work environment

-

Fan power: sufficient to maintain positive pressure and stable laminar flow

-

-

Casing materials appropriate for food environments

FFU often operates in humid environments, sometimes exposed to cleaning chemicals. Therefore, the casing must resist corrosion:-

Electrostatic coated steel: cost‑effective

-

Stainless steel 304: high corrosion resistance, suitable for wet zones

-

-

Ease of maintenance and device durability

-

Modular design for easy removal and cleaning of filters

-

Integrated differential pressure gauge to monitor filter life

-

A device lifespan of 5–10 years with periodic maintenance

-

| Application area | Clean class | Recommended filter | FFU casing material | Notes |

|---|---|---|---|---|

| Product packaging room | Class 100–1000 | HEPA | Stainless steel 304 | Controls dust & microbes |

| Primary processing area | Class 10,000 | HEPA | Coated steel | Emphasize high airflow |

| Cold storage / warehouses | Class 100,000 | Pre-filter + HEPA | Stainless steel 304 | Moisture resistant, easy to clean |

| Additive mixing rooms | Class 1000 | ULPA | Stainless steel 304 | Requires strict control |

Selecting the right FFU helps businesses meet food safety standards and optimize long-term operational costs. If you need assistance designing an airflow system specific to your factory zones, VCR can provide in‑depth consultancy.

Read more: Cleanroom FFU: How to calculate air flow according to room area

3. Benefits of installing properly specified FFU in food factories

In the food processing industry, maintaining a clean and safe production environment is crucial to protect consumer health and brand reputation. Investing in properly designed FFU systems brings many long-term benefits, not only in product quality but also in operational efficiency:

-

Ensure food hygiene and safety standards

FFU systems maintain stable air cleanliness, helping control microbes, fine dust, and airborne contaminants. This aids factories to:-

Comply with standards like ISO 22000, HACCP, GMP

-

Pass customer audits and international partner assessments

-

Expand export potential

-

-

Prevent cross‑contamination from ambient air

One major risk in food production is cross‑contamination between process stages. FFUs create unidirectional (laminar) clean airflow, which:-

Prevents return airflow carrying dust or microbes

-

Protects finished product areas from external contamination

-

Maintains positive pressure between rooms to keep out unclean air

-

-

Extend lifetime of HVAC and other equipment

Installing FFUs at key points helps preprocessing filters to remove most particles. This:-

Reduces load on central HVAC or AHU systems

-

Prevents clogging, pressure loss, or premature failure

-

Extends service intervals and lowers replacement costs

-

-

Optimize long‑term operational cost

Compared to centralized air filtration systems, FFUs are modular and scalable. This offers:-

Incremental investment by zone instead of full upfront cost

-

Energy savings via variable fan speed control

-

Easy maintenance without halting full production

-

When FFUs are selected and installed correctly, companies not only invest in current production quality but also build a sustainable foundation for the future. This is critical for food factories aiming to meet stricter cleanliness, hygiene, and efficiency standards.

Read more: What Is an FFU Fan Filter Unit and Why Is It Essential in Food Cleanrooms?

4. Reputable FFU supplier – key criteria to choose

Installing FFU (Fan Filter Unit) is more than picking a good air cleaner—it’s a holistic project involving design, engineering, and after‑sales support. Thus choosing a trusted supplier is critical to ensuring efficient, stable clean-air operation that meets food industry standards.

Here are important criteria to evaluate potential suppliers:

-

Experience in food factory implementations

The food industry has unique production features, strict hygiene requirements, and high continuity demand. A supplier with real project experience will understand:-

Clean class segmentation by zone

-

Layout design that does not interfere with production

-

Microbial, dust, and odor control specific to your product type

-

-

Full‑service solution: consulting – design – installation – maintenance

Instead of selling a standalone unit, a reputable supplier should deliver a turnkey service:-

Consultancy to determine optimal clean-air layout

-

Design drawings of FFU placement, airflow, cleanliness

-

Correct technical installation with minimal production disruption

-

Routine maintenance and provision of spare parts

This approach saves time, cost, and ensures stable system operation.

-

-

FFU with full quality certifications

A properly qualified FFU must include documentation:-

Test report verifying HEPA or ULPA performance

-

CO/CQ: certificate of origin and quality

-

ISO compliance reports when integrating into cleanroom systems

These documents are essential for internal audits, HACCP, ISO, or dealings with foreign partners.

-

-

Support for customization based on factory requirements

Each factory has a unique layout, ceiling, duct system, or module constraints. A serious supplier should offer:-

Custom fabrication for special dimensions

-

Selection of filter types per zone (HEPA/ULPA, with or without prefilter)

-

Adjustable airflow, fan control, sensor integration, pressure gauges

-

VCR – Leading FFU supplier for the food industry in Vietnam

With over 10 years of experience in clean-room equipment, VCR is a trusted partner of many leading food manufacturers in Vietnam. Reasons customers choose VCR:

-

Genuine FFU products imported from Korea, Taiwan, Japan

-

Specialized engineers in clean‑air for food factories

-

A large warehouse capable of fulfilling bulk FFU orders rapidly

-

Transparent warranty and on‑site technical support

Choosing the right supplier ensures your clean-air system is reliable, efficient, and gives you peace of mind during operation.

Read more: 5 Keys considerations for selection Fan Filter Unit for Cleanroom

5. VCR’s FFU – optimal solutions for the food industry

Food production demands stringent control over dust, microbes, and humidity. Factories need filtration devices that are durable, clean, and stable even under harsh conditions. Recognizing this, VCR offers specialized FFU models built to satisfy technical and hygiene standards for food factories.

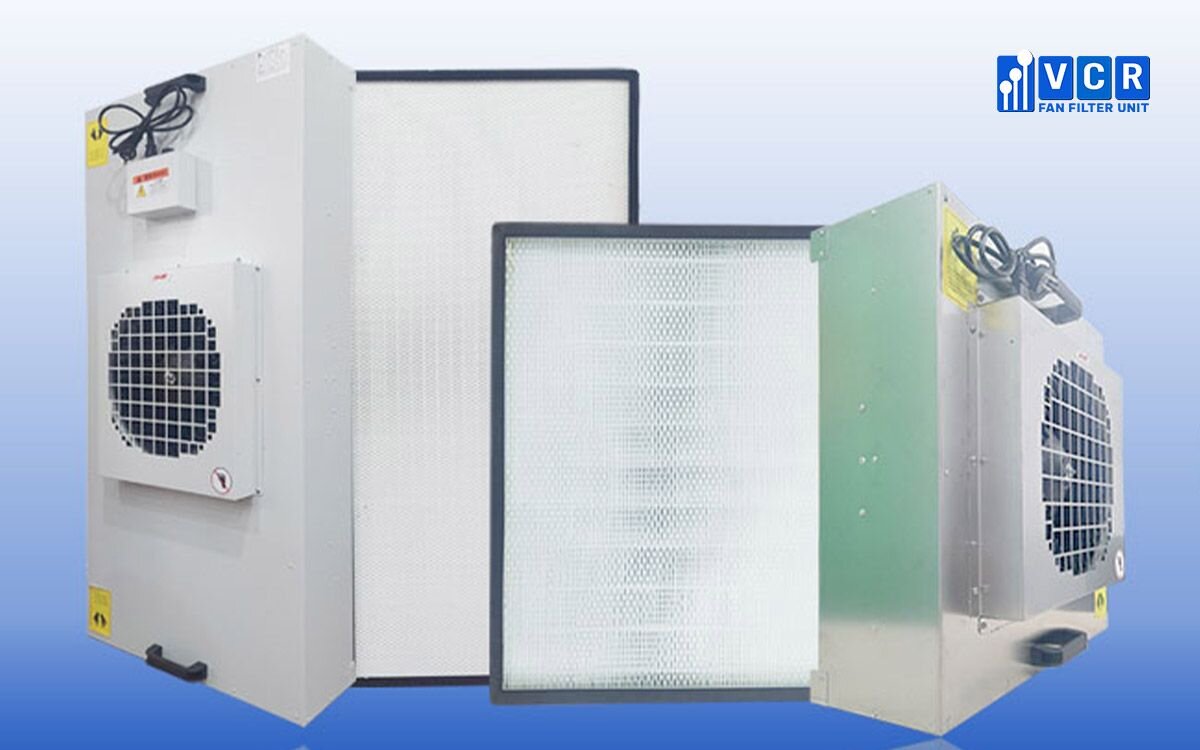

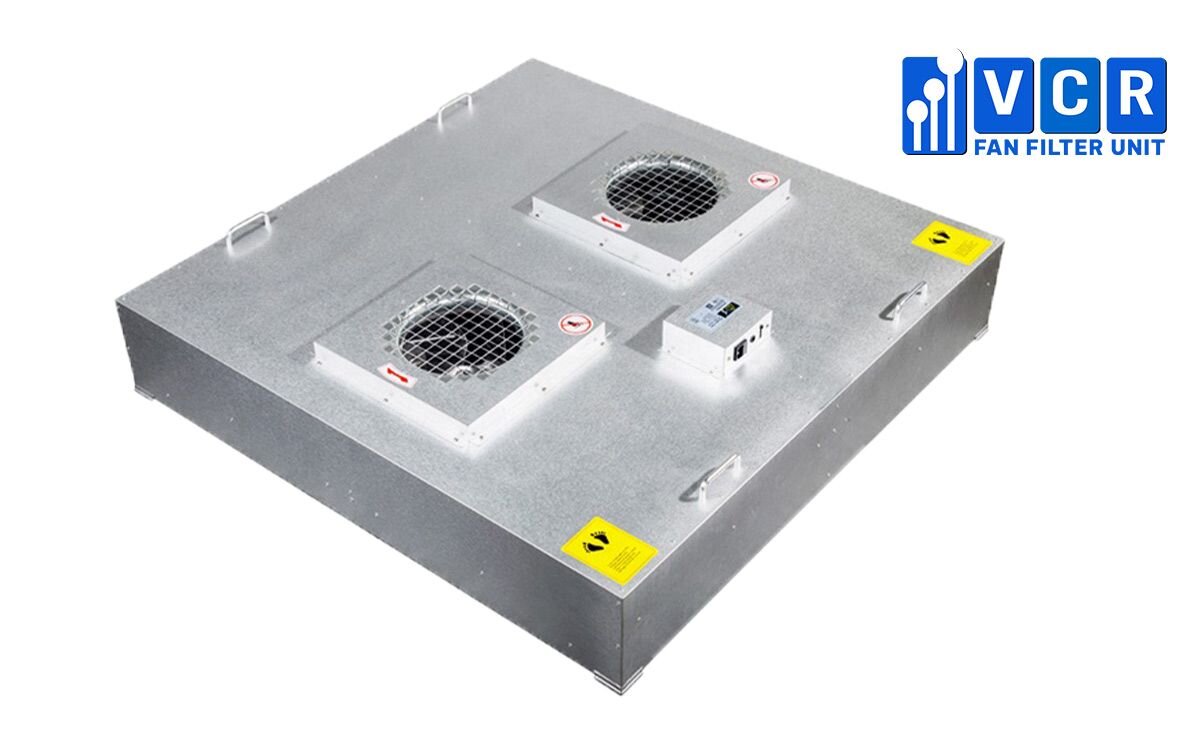

Typical FFU models for food factories:

-

Stainless steel 304 FFU

-

Casing made from corrosion-resistant stainless steel

-

Ideal for wet zones, meat, seafood processing

-

Easy to clean and resistant to strong cleaning chemicals

-

-

Variable-speed fan FFU

-

Allows adjusting airflow per production stage

-

Saves energy and extends filter lifespan

-

-

Modular FFU design

-

Flexible arrangement in false ceilings or room modules

-

Simple replacement or expansion without disrupting production

-

Real-world applications in the food sector:

-

Processing zones for seafood, fresh meat (requiring microbial and humidity control)

-

Packaging rooms for final products (cleanliness classes from 1000–10,000)

-

Canned food and beverage factories (removing odors, dust, preserving flavor)

-

Cold storage and finished goods warehouses (maintaining air hygiene during long storage)

Supporting services from VCR

Beyond equipment supply, VCR accompanies clients through the entire system lifecycle with professional technical services including:

-

ISO cleanroom testing and certification

-

Calibration services per ISO/IEC 17025

-

Upgrading existing FFUs to energy-saving versions

-

Consultation on operation and routine maintenance

Why choose VCR’s FFU?

-

Genuine imports from Taiwan, Korea

-

12‑month warranty, on-site technical service

-

Large stock, fast nationwide delivery

-

Customization support based on factory-specific requirements

With robust technical capacity and responsive inventory, VCR commits to providing comprehensive FFU solutions, optimizing cost, and ensuring the highest hygiene standards for food factories.

Read more: Supplier of FFU - Fan Filter Unit meeting GMP standards in Vietnam

6. FAQ – Common FFU questions for food processing factories

Q: Should I use HEPA or ULPA FFU in fresh food processing zones?

A: For zones like meat or seafood processing, HEPA is usually optimal. HEPA filters remove 99.97% of particles ≥0.3 µm, meeting cleanliness Class 1000–10,000 — suitable for microbial control. If you have more stringent cleanliness demands or export to strict markets (Japan, EU), you may consider ULPA for meeting Class 100–1000 levels.

Q: Can FFUs be used in humid or high-temperature environments?

A: Yes. In humid or high‑moisture areas like fish or meat prep rooms, you should select FFUs with stainless steel 304 casing (corrosion-resistant). Also use fans rated for heat and motor protection to ensure longevity under harsh conditions.

Q: How often should the FFU filter be replaced in food factories?

A: The typical lifespan of an FFU filter is 6 to 12 months, depending on air contamination, usage frequency, and filter type. You should equip differential pressure gauges to monitor and replace filters once pressure exceeds safe limits to maintain filtration efficiency and air cleanliness.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Dat VCR