FFU is a device that creates a one-way clean air flow in a clean room, helping to maintain the cleanliness level according to ISO standards. Checking the air velocity of the FFU is an important step to ensure air filtration efficiency, pressure stability and prevent cross-contamination in the production environment.

- 1. What is an FFU and why should its air velocity be measured?

- 2. Equipment needed to measure FFU air velocity

- 3. Procedure for measuring FFU air velocity in an ISO cleanroom

- 4. How to troubleshoot if FFU air velocity is out of specification

- 5. Reference documents and standards

- 6. Frequently Asked Questions

- 7. Need support for FFU validation or cleanroom maintenance?

1. What is an FFU and why should its air velocity be measured?

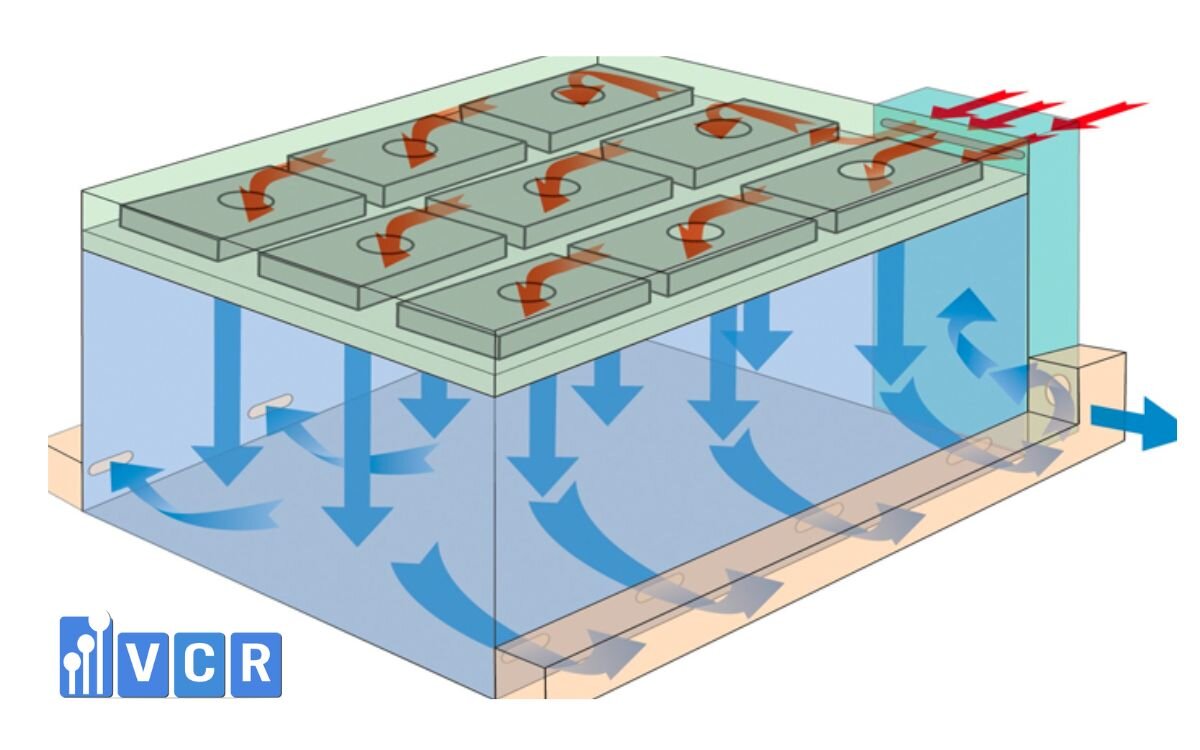

An FFU (Fan Filter Unit) is a device that integrates a fan and a HEPA/ULPA filter, mounted directly onto cleanroom ceilings to create unidirectional airflow (laminar flow). This unit plays a crucial role in maintaining cleanliness levels from ISO Class 5 to ISO Class 8, especially in industries such as pharmaceuticals, electronics, food, and cosmetics.

The role of air velocity in FFU performance

To meet the desired ISO cleanliness level, the air velocity from the FFU must match design standards. This is particularly critical in sensitive zones like weighing rooms, cosmetic filling areas, or SMT lines in electronics manufacturing.

Air velocity within specification helps to:

- Maintain laminar airflow: Ensures clean air moves downward continuously, sweeping away particles and microorganisms.

- Prevent particle accumulation: Reduces cross-contamination and quality deviations.

- Stabilize room pressure: Supports pressure differentials between cleanroom zones.

When should FFU air velocity be measured?

|

Scenario |

Reason for testing |

|

After initial installation |

Ensure FFU operates according to ISO design requirements |

|

Periodic validation (typically every 6-12 months) |

As required by GMP, ISO 14644-3, and internal SOPs |

|

Signs of malfunction |

e.g., pressure drops, visible particle buildup, poor filtration, filter replacement |

Note: Failing to measure air velocity correctly may lead to incorrect ISO classification and affect the entire production process.

See more: Supplier of FFU - Fan Filter Unit meeting GMP standards in Vietnam

2. Equipment needed to measure FFU air velocity

To accurately assess FFU performance in an ISO cleanroom, choosing the right air velocity measuring device is essential. Depending on the technical requirement and desired accuracy, the following equipment may be used:

|

Device |

Description |

Key Advantages |

|

Anemometer |

Common types: vane and thermal |

Easy to use, ideal for spot-checks |

|

Hot-wire anemometer |

Uses a sensitive thermal wire probe |

High accuracy, suitable for multi-point measurements |

|

Flowhood (Hood Capture) |

Captures total airflow from FFU for volumetric output (CMH/CFM) |

Provides an overview of FFU performance, ideal for initial commissioning |

Suggested use by purpose:

- Quick routine checks: Vane anemometer

- Detailed ISO-compliant analysis: Hot-wire anemometer

- Overall airflow measurement: Flowhood

Many EU-GMP-compliant facilities use a combination of devices to cross-check and minimize measurement error.

3. Procedure for measuring FFU air velocity in an ISO cleanroom

Properly measuring FFU air velocity is mandatory for validating cleanroom compliance with ISO 14644. Below is a 4-step procedure commonly used in pharmaceutical, electronics, and cosmetics manufacturing:

1. Preparation before measurement

- Ensure the FFU is running stably, with no abnormal noise

- Close all cleanroom doors and airlocks

- Clean the measurement area to avoid interference from dust or moisture

2. Define measurement points

To ensure accuracy and representativeness, divide the FFU surface into equal square grids:

|

FFU Type |

Grid Division |

Minimum Measurement Points |

|

Standard FFU (600x600 mm) |

Divide into 9 squares of 30x30 cm |

5 points |

|

Large FFU (≥600x1200 mm) |

Divide into 9-12 squares depending on size |

At least 9 points |

Note: Label measurement points for easier tracking and comparison.

3. Conduct measurements

- Position the sensor probe approximately 15 cm below the FFU surface

- Measure each point from left to right, top to bottom

- Repeat measurements 2-3 times per point, then calculate the average

4. Calculation and evaluation

After collecting data from all points:

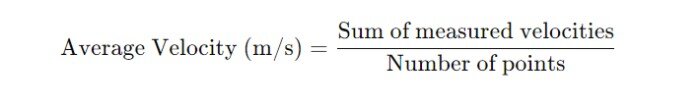

Calculate average air velocity using the formula:

Compare against ISO requirements:

|

ISO Class |

Required Air Velocity (m/s) |

|

ISO 5 |

≥ 0.45 m/s |

|

ISO 6-8 |

0.3 - 0.45 m/s |

Check deviation between points:

- Maximum allowable variation is ±15%

- Exceeding this may indicate issues with fans, filters, or airflow design

A valid FFU inspection report should include point-by-point readings, on-site photos, and a final assessment compared with ISO standards.

See more: Safeguarding Your Semiconductor Cleanroom: A Practical Guide to FFU Maintenance

4. How to troubleshoot if FFU air velocity is out of specification

During FFU validation, if the measured air velocity does not meet ISO requirements, it is crucial to quickly identify the cause and implement corrective actions to avoid impacting cleanliness levels and system performance.

Below are common troubleshooting steps applied in cleanroom facilities:

1. Replace the prefilter or HEPA filter

Reason: A clogged filter reduces airflow through the FFU.

Solution:

- Replace the prefilter if used for more than 3 months (depending on conditions)

- Check HEPA differential pressure; if abnormally high → replacement is needed

Practical tip: After replacing filters, remeasure air velocity to confirm improvement.

2. Adjust fan speed

Reason: Some FFUs are equipped with controllers or inverters.

Solution:

- Increase fan speed via a dial or digital controller

- Ensure supply voltage is within specification (typically 220-240V)

Note: Only applicable to FFUs with adjustable speed. For fixed-speed models, proceed to the next step.

3. Check power supply & motor start capacitor

Reason: Low voltage or faulty capacitor can result in weak airflow from the FFU.

Solution:

- Measure voltage at the FFU’s power source

- Use a multimeter to test motor start capacitor (usually 2-10μF)

- Replace the capacitor if measured value deviates by more than 10% from rated spec

Common issue in older FFUs or those in high-humidity environments.

4. Review HVAC/cleanroom design drawings

Reason: Inadequate system design may cause insufficient airflow.

Solution:

- Check for return air obstructions or blocked airflow paths

- Compare designed total airflow per room (CFM) with current number of FFUs

- Ensure FFU placement is not blocked or causing turbulence

This step may require support from experienced cleanroom engineers or consultants.

Conclusion: Troubleshooting should follow a logical sequence from simple to complex: start with filter checks, then fan adjustments, and finally review HVAC design. All changes should be documented to support ISO/GMP audits.

See more: Laminar Airflow Cleanroom Control in FFUs

5. Reference documents and standards

To ensure proper FFU airflow testing in an ISO cleanroom, manufacturers must follow these standards and guidelines:

1. ISO 14644-3: Methods of Test

A key part of the ISO 14644 cleanroom standard series.

Covers technical test methods including:

- Air velocity measurement

- Airflow visualization

- HEPA filter leak testing

Serves as the basis for developing internal SOPs for FFU validation.

Applicable for facilities seeking ISO 14644-1 classification.

2. GMP WHO/EU - Guidelines on airflow validation

Examples:

- Annex 1 (EU-GMP): Requires unidirectional airflow testing in sterile production areas

- WHO TRS 961 Annex 5: Outlines airflow speed, direction, and pressure validation

These documents clearly define test points required in cleanroom qualification.

Especially critical for pharmaceutical, cosmetic, and bioproduct facilities.

3. Internal SOP for cleanroom validation (GMP-based)

Every facility should establish Standard Operating Procedures (SOPs) for periodic validation.

SOPs should include:

- Validation frequency (typically every 6 months)

- Equipment used and calibration methods

- Data recording templates

- Pass/fail criteria aligned with ISO/GMP

Proper SOP documentation helps facilities pass audits from health authorities, certification bodies, or international clients.

Complying with these standards ensures optimal cleanroom performance and increases credibility when entering regulated markets such as the EU, Japan, and the US.

See more: HEPA Filter Leak Testing in FFUs – Fan Filter Unit

6. Frequently Asked Questions

1. Can I use a low-cost air velocity meter?

→ No.

Cheap instruments often have high errors and lack the sensitivity and accuracy required for cleanroom environments. Incorrect results may lead to misclassification and audit failures.

2. Which FFU models allow air velocity adjustment?

→ Models with integrated inverters or speed control boards.

Modern FFUs can be adjusted via built-in controls or integrated BMS systems. This feature is especially useful when airflow must be fine-tuned after filter changes or design modifications.

3. How often should FFU air velocity be checked?

→ At least every 6 months.

According to GMP and ISO 14644-3 guidelines, FFU airflow should be validated periodically or whenever changes occur in design, airflow, or HEPA filters.

4. How does air velocity affect ISO classification?

→ It directly determines the cleanroom class.

If airflow is too low, particles remain suspended → exceed ISO particle limits.

If airflow is too high, turbulence may occur → disrupt laminar flow, affecting test results.

7. Need support for FFU validation or cleanroom maintenance?

Measuring FFU air velocity is a critical step in evaluating cleanroom performance to ISO standards. Whether in pharmaceutical, electronics, or food manufacturing, failing to meet air velocity requirements can result in:

- Loss of unidirectional flow

- Particle buildup and contamination risk

- ISO classification failure or GMP audit issues

Therefore, periodic validation and prompt troubleshooting are essential.

Contact the VCR technical team for:

- FFU air velocity measurement with ISO-calibrated equipment

- Troubleshooting and performance improvement advice

- Full validation report compliant with GMP/ISO standards.

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Diep VCR