Fan Filter Units (FFUs) have established themselves as a dominant force in cleanroom air purification across various industries, including the demanding world of semiconductor manufacturing. Their ability to overcome the limitations of traditional systems makes them a compelling choice for achieving and maintaining critical air quality standards.

This article dives deeper into the specific applications of FFUs in semiconductor cleanrooms, highlighting their advantages and exploring their broader applications.

Semiconductor Industry Challenges

Semiconductor cleanrooms require large spaces with exceptionally high cleanliness levels (Class 100, Class 1000). Traditional air purification systems often struggle to meet these demands, burdened by

- High Costs: Extensive ductwork, central air handling units, and lengthy construction lead to significant upfront investments.

- Energy Consumption: The continuous operation of centralized systems results in substantial energy usage.

- Time Constraints: Construction phases can significantly delay production start-up and impact overall efficiency.

- Flexibility Limitations: Modifying and scaling traditional systems based on changing needs can be cumbersome and costly.

See more: FFU Count for Cleanroom

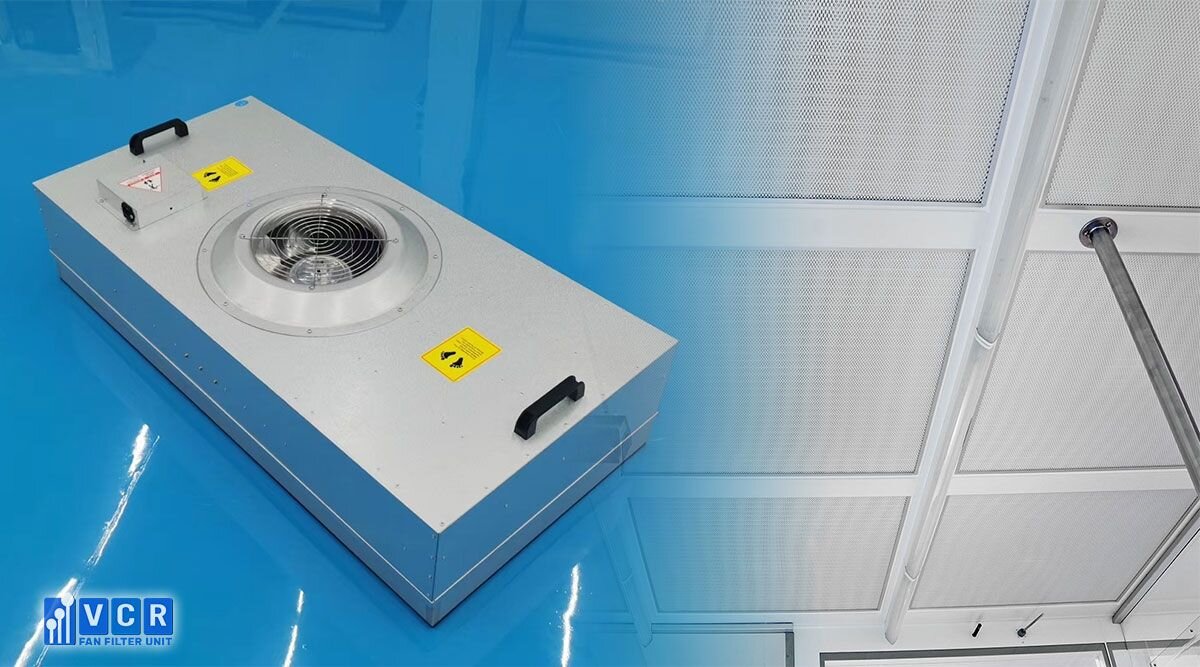

FFUs: A Tailored Solution

FFUs address these challenges with their unique features and offer several key advantages:

- Modular Design: Individual, self-contained FFUs enable flexible installation and modular scalability. This allows for adjustments in air supply based on specific cleanroom zones or evolving production needs.

- Cost-Effectiveness: Compared to traditional systems, FFUs require minimal ductwork and construction, leading to lower initial and installation costs.

- Energy Efficiency: The decentralized nature of FFUs reduces energy consumption by eliminating extensive ductwork and minimizing air leakage.

- Fast Deployment: Their modular design enables faster installation and operational readiness, minimizing production delays.

Types of FFUs in Semiconductor Cleanrooms

- Laminar Flow FFUs: These units provide a unidirectional, downward airflow, ideal for sensitive processes requiring a controlled air path.

- Multi-Directional FFUs: These FFUs distribute air in multiple directions, suitable for general cleanroom areas needing overall air cleanliness control.

Advanced functionality of FFU

While FFU excel in core air purification, additional features cater to specific semiconductor cleanroom needs:

- Integrated Static Pressure Boxes: These boxes house auxiliary equipment like lights, pipes, and neutralizing devices, maximizing ceiling space.

- Negative Pressure Sealing: FFUs inherently create a negative pressure environment, minimizing the risk of air leaks and contamination during filter changes.

Expert Considerations to use Fan Filter Unit

- Matching Cleanliness Levels: Select Fan Filter Unit with HEPA filters certified for the required cleanroom class.

- Airflow Pattern Selection: Choose laminar flow FFUs for sensitive processes or multi-directional units for general areas.

- Energy Efficiency: Opt for FFUs with energy-saving features like variable speed motors and intelligent control systems.

- Maintenance Schedule: Implement a regular maintenance schedule for filter replacements and performance checks.

See more: Maintenance FFU for Semiconductor Cleanroom

Beyond Semiconductors: A Broader Reach

While the focus has been on semiconductor cleanrooms, FFUs offer their benefits across various industries:

- Pharmaceutical Cleanrooms: Ensuring product sterility and preventing contamination in pharmaceutical manufacturing.

- Hospital Cleanrooms: Maintaining aseptic environments for critical medical procedures.

- Laboratories: Protecting sensitive research experiments and personnel from airborne contaminants.

- Food Processing Cleanrooms: Guaranteeing food safety and hygiene control throughout production.

By leveraging the versatility and efficiency of FFUs, cleanrooms across diverse industries can achieve and maintain the pristine air environments crucial for their operations. The careful selection of FFU types and features, combined with expert considerations, ensures a controlled and clean environment for success.