The relentless pursuit of quality in high-tech industries like electronics, pharmaceuticals, and food production necessitates meticulous control over manufacturing environments. Cleanrooms, with their stringent air purity requirements, play a crucial role in safeguarding product integrity.

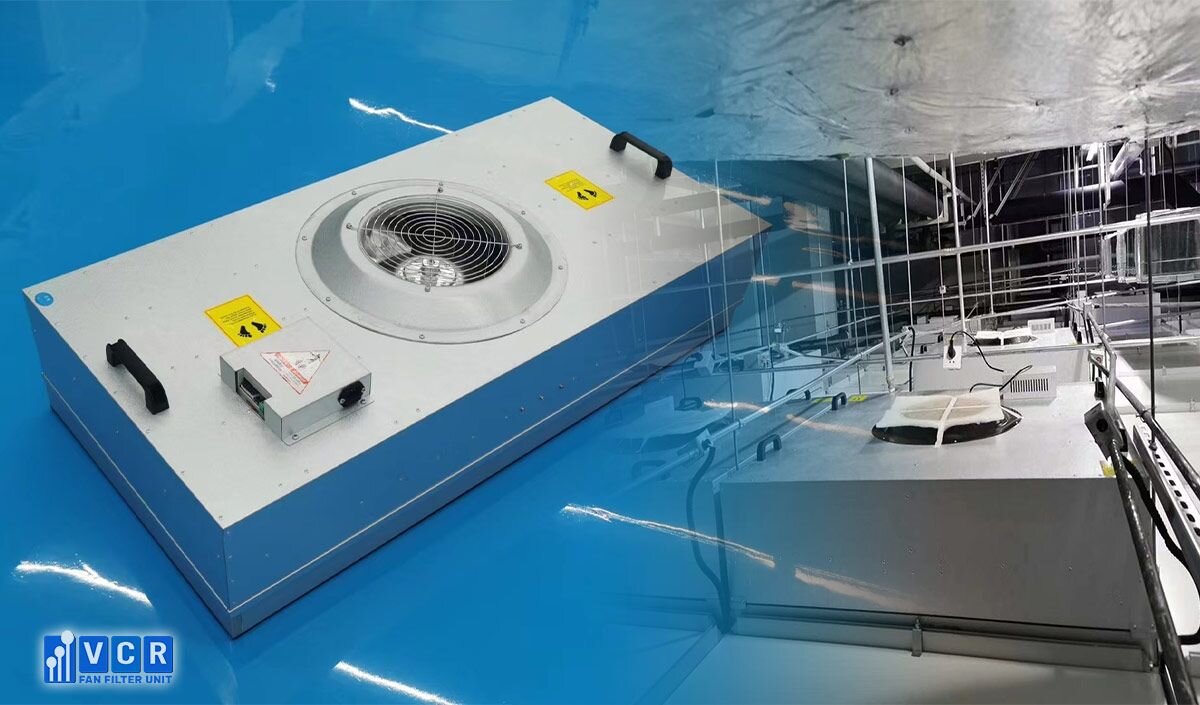

Fan filter units (FFUs) have emerged as indispensable tools in maintaining these controlled environments, offering a compact and adaptable solution for air filtration and laminar airflow.

FFUs: Powerhouse of Purification

An FFU integrates a fan and a high-efficiency filter (HEPA or ULPA) within a single unit, providing self-contained air purification at the point of use. Their modular design and ease of installation make them highly versatile, enabling flexible configuration within cleanrooms of various sizes and shapes. Additionally, the ability to adjust their air velocity and volume empowers precise control over the cleanroom's airflow profile, further enhancing environmental control.

See more:

Laminar Airflow Cleanroom Control in FFUs

Unveiling the Control Toolbox

The heart of an FFU lies in its control system, dictating its operational effectiveness and energy efficiency. The choice of control mode hinges on several factors, including cleanroom size, desired precision, budget constraints, and operational complexity. Here's a deeper dive into the prevalent options:

1. AC Motor Control:

- Multi-speed switch control: Offers a basic approach with pre-defined fan speeds, suitable for smaller cleanrooms with less stringent requirements.

- Voltage and speed control: Provides variable speed control by adjusting the voltage supplied to the motor, offering more flexibility than multi-speed switches.

- Frequency conversion speed control: Employs an inverter to directly control the motor's frequency, enabling the most precise and energy-efficient speed regulation.

2. DC Motor Control:

- Computer group control: Leverages a distributed control system for centralized monitoring and management of multiple FFUs. This method excels in large cleanrooms, offering individual FFU control, real-time performance data, and energy-saving features.

- Remote control: While optional, it can be integrated with the computer group control system for convenient monitoring and adjustments from a distance.

Striking the Balance: Weighing the Options

Each control mode presents its own set of advantages and drawbacks. While the DC computer group control system reigns supreme in terms of flexibility, energy efficiency, and centralized management, its higher initial cost and maintenance demands might deter budget-conscious users. AC motor control methods, particularly frequency conversion, offer a cost-effective alternative, albeit with potential compromises in precision and centralized control.

See more: Advantages of FFU Systems

The Future of FFU Control

As technology evolves, FFU control systems are poised to become even more sophisticated. Integration with building management systems, predictive maintenance capabilities, and advanced communication protocols are some exciting possibilities on the horizon. These advancements will further optimize cleanroom environments, ensuring consistently high product quality and operational efficiency.

We hope this revised version meets your expectations and provides a valuable resource for understanding FFU control modes in industrial cleanrooms.

See more: Selection Fan Filter Unit for Cleanroom