The FFU (Fan Filter Unit) is an air filtration device that integrates a fan and a HEPA filter, helping to maintain a sterile environment in cosmetic filling areas. This solution enables factories to meet GMP/ISO 22716 standards, prevent cross-contamination, protect products, and optimize production efficiency.

- 1. What is an FFU? Why is it important in a cosmetics filling room under GMP?

- 2. Criteria for selecting an FFU for a cosmetics filling room

- 3. VCR – Reputable FFU supplier for the cosmetics industry

- 4. FFU models suitable for cosmetics filling rooms

- 5. Guide to maintenance and correct filter replacement of FFU

- 6. FAQ – Frequently Asked Questions

1. What is an FFU? Why is it important in a cosmetics filling room under GMP?

Definition and structure of an FFU (Fan Filter Unit)

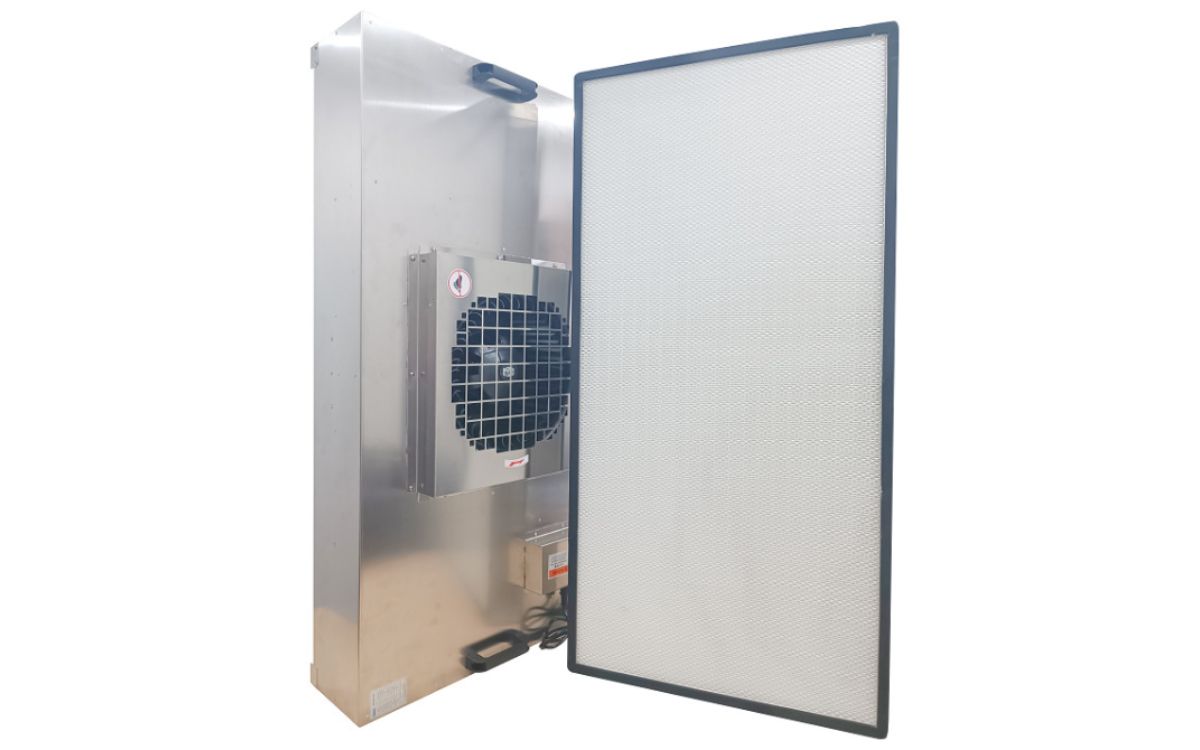

An FFU (Fan Filter Unit) is an air-filtration device that integrates a fan and a HEPA or ultra-fine particle filter, typically installed in the ceiling of a cleanroom. The FFU consists of three main components:

-

A fan: forces air flow through the filter.

-

A HEPA/ULPA filter: removes up to 99.99% – 99.9995% of fine particles and microorganisms.

-

A housing/frame: usually made of stainless steel or electro-painted steel, corrosion resistant.

This device operates independently and continuously, ensuring the maintenance of stable cleanliness levels in the space.

Role of the FFU in a cosmetics filling room

In the cosmetics-filling process — where the product comes into direct contact with the environment — any dust particles, microorganisms or contaminants can cause contamination and affect finished product quality. The FFU helps to:

-

Create a clean environment meeting ISO Class 5–8 depending on the area.

-

Prevent microbial contamination in the air.

-

Maintain positive pressure to keep dirty air from entering.

-

Protect the product and extend the service life of the filling equipment.

What does GMP require for air-control in a filling room?

Under Good Manufacturing Practices (GMP), environmental control is mandatory — especially in filling and sterile packaging areas. Key requirements include:

-

Air must be filtered through HEPA.

-

Pressure, temperature and humidity must be continuously controlled.

-

One-directional airflow or positive pressure must be present in the filling room.

-

Cleanroom class inversions (i.e., airflow reversals) must be avoided.

The FFU is an effective solution to meet these requirements without investing in a complex central AHU (Air Handling Unit) system.

Why is the FFU indispensable?

-

Easy to install — suitable for both new systems and retrofits.

-

More energy-efficient compared to a central system.

-

Provides stable cleanliness over time.

-

Supports businesses in obtaining GMP, ISO 22716 certification.

For cosmetics factories, especially during the filling stage — where high sterility and cleanliness are required — using an FFU is not just a choice but a standard requirement.

Read more: Latest price list of FFU Fan Filter Unit used in Cosmetic factory

2. Criteria for selecting an FFU for a cosmetics filling room

To ensure the cosmetics filling room meets GMP standards, businesses need to choose cleanroom FFUs based on technical criteria suitable for required cleanliness, durability and stable operation in a continuous-production environment. Here are five important factors:

Filter efficiency (HEPA/ULPA) – Ensure Class 100–100,000 cleanliness.

- FFU must be equipped with HEPA (High Efficiency Particulate Air) or ULPA (Ultra Low Penetration Air).

- Minimum filtering efficiency:

-

HEPA H13: ≥ 99.99% for particles ≥0.3 µm.

-

HEPA H14: ≥ 99.995%.

-

ULPA: ≥ 99.9995% for particles ≥0.12 µm.

-

- Suitable for cleanliness levels from ISO Class 5 to Class 8 (equivalent to GMP Grade A–D).

Noise level, air-flow volume and static pressure

- Typical airflow: 800 – 1500 m³/h, depending on room area and air supply requirement.

- Higher static pressure helps ensure uniform airflow through the filter without performance drop.

- Noise level ≤ 50 dB: ensures a quiet working environment, avoids impacting operator comfort.

Construction materials – Durable and corrosion-resistant

- Common materials:

-

-

-

Stainless steel 304: corrosion-resistant, easy to clean, suitable for high humidity environments.

-

Electro-painted steel: cost-effective, good oxidation resistance.

-

-

- The surface must be smooth, dust-free, and chemically stable.

Size compatible with cleanroom ceiling system

- Standard sizes: 1175 × 575 mm or 1175 × 1175 mm.

- FFU must match the ceiling grid (module) of the cleanroom to prevent air leakage.

- Custom sizes available for specific plant design.

Energy saving and easy maintenance

- DC-fan design uses less energy compared to traditional AC fans.

- Modular design allows quick filter replacement without disrupting production.

- Ability to integrate a speed controller and remote pressure monitoring.

Read more: Can FFU (Fan Filter Unit) Be Connected to an Air Duct?

3. VCR – Reputable FFU supplier for the cosmetics industry

As one of the pioneering companies in cleanroom solutions, VCR proudly offers FFUs that fully meet the stringent requirements of the GMP & ISO 22716 certified cosmetics production industry.

Experience in implementation

-

VCR has executed hundreds of projects for filling, packaging, and cleanrooms Class 100 – 10,000 for domestic and international cosmetics brands.

-

Team understands special requirements of cosmetics industry such as microbial control, positive pressure, sterile filling zones.

-

Technical staff with years of experience, provide optimal consultancy by factory model.

FFU quality & certification

-

The FFU products supplied by VCR are independently certified according to ISO 14644-1 standard, ensuring indoor air cleanliness during operation.

-

Filtering efficiency up to 99.9995% (HEPA/ULPA), suitable for Grade A–B zones in cosmetics factories.

-

Quiet operation, low noise, energy-saving thanks to premium DC fans.

Design and installation

-

VCR provides site survey service, produces layout drawing of FFU according to ceiling system and required cleanliness class.

-

Quick installation without affecting production lines.

-

Integration support with central filtration system (AHU), air-flow speed control, pressure sensors.

Warranty & after-sales support

-

Warranty period: 12-24 months, periodic inspection support, filter replacement as recommended.

-

Technical team spread across the three regions of Vietnam, ready 24/7 support when incidents occur.

-

Genuine spare parts and replacement filters provided, ensuring device lifespan and performance.

Read more: Safeguarding Your Semiconductor Cleanroom: A Practical Guide to FFU Maintenance

4. FFU models suitable for cosmetics filling rooms

Depending on the required cleanliness class, ceiling structure and filling line design, businesses can select different FFU models to optimize operational efficiency and investment cost. Below are three prominent lines provided by VCR for GMP-certified cosmetics factories.

Comparison table (excerpt):

-

Model: FFU VCR-H13: Airflow 1000 – 1200 m³/h; Size 1175 × 575 × 330 mm; Filter HEPA H13 ≥ 99.99%; Material: Inox 304.

-

Model: FFU VCR-H14: Airflow 1000 – 1500 m³/h; Size 1175 × 575 × 330 mm; HEPA H14 ≥ 99.995%; Material: Electro-painted steel.

-

Model: FFU ULPA: Airflow 800 – 1200 m³/h (project-specific); ULPA ≥ 99.999%; Material: optional Inox/Steel.

Features of each line:

-

VCR-H13: Suitable for Class 1000 – 10,000 cleanrooms, often used in filling or pre-sterile zones. Inox 304 material makes it easy to clean and corrosion-resistant.

-

VCR-H14: Higher filtration efficiency, suitable for more stringent cleanliness zones such as sterile filling. Cost-effective due to electro-painted steel material.

-

FFU ULPA: Ideal for Grade A/B zones — extremely sensitive areas in cosmetics production line. Size and airflow can be customized according to plant design. Suitable for Class 100 and above.

Read more: Unveiling the Advantages of FFU Systems in Cleanrooms

5. Guide to maintenance and correct filter replacement of FFU

To ensure the FFU system always operates stably and maintains GMP-standard cleanliness in the cosmetics filling room, businesses need to establish a scientific and strict maintenance and filter replacement process. Below are essential instructions:

-

Filter replacement cycle (HEPA/ULPA): 6 – 12 months depending on conditions

-

For typical cosmetics production environment: replace HEPA after 12 months of continuous operation.

-

For sterile filling areas or high contamination risk: shorten cycle to 6-9 months.

-

Do not reuse old filters because it reduces filtration efficiency and affects product quality.

-

-

Check airflow and differential pressure regularly

-

Install a differential pressure gauge to monitor pressure before and after the filter.

-

If the pressure difference exceeds allowable threshold (often > 250 Pa): check and replace filter immediately.

-

Abnormal airflow reduction is also a sign of filter blockage.

-

-

Clean the machine body and fan motor periodically

-

Remove protective grille and clean dust with a soft cloth; avoid strong chemicals.

-

Lubricate fan motor (if required) and check bearings, power cables.

-

Ensure the unit is always dry, no water accumulation or dust build-up inside.

-

-

Important note when replacing FFU filters

-

Use HEPA/ULPA filters that meet ISO standards — same model as the original for compatibility.

-

Install in the correct airflow direction; ensure perfect sealing between frame and filter (use rubber gasket or specialist sealant if needed).

-

After replacement, re-test efficiency and static pressure to ensure the device operates within specification.

-

Read more: Provider of Cleanroom FFU for SMT – Controlling Ultrafine Particles

6. FAQ – Frequently Asked Questions

Q: Is FFU necessary for all rooms in a cosmetics factory?

A: No. FFUs are only truly necessary for areas requiring high cleanliness, such as filling rooms, sterile packaging or raw-material weighing rooms. These are zones where the product directly contacts the environment and where microbial contamination risk is higher. For support areas (warehouse, corridor, office), a coarse filtration system or AHU may suffice.

Q: Can a HEPA filter be reused after cleaning?

A: No. HEPA filters are single-use. Their ultra-fine filter structure is highly sensitive and cannot be cleaned by standard methods without damage. Re-using an expired filter may lead to large reductions in filtering efficiency, failing to remove fine particles and microorganisms—posing risk to product quality.

Q: Does FFU generate a lot of noise?

A: Not if the right equipment is chosen. High-quality FFU models, especially those using modern DC fans, typically have noise levels under 50 dB — similar to a quiet office. This ensures a comfortable working environment for operators, particularly in long-duration production runs.

Are you looking for a GMP-standard air-control solution for a cosmetics filling room? VCR offers a full set of high-performance FFU devices that suit all cleanliness classes and plant designs.

Why choose VCR?

-

Specialized technical team in the cosmetics industry.

-

FFUs certified to ISO 14644 — high HEPA/ULPA filtering efficiency.

-

Supports nationwide layout design, installation.

-

Clear warranty policy, readily available spare parts.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://ffu.com.vn/

Dat VCR