Installing a fan filter unit (FFU) in a cleanroom demands meticulous attention to detail and stringent protocols. Improper installation can compromise the unit's performance, jeopardizing cleanroom air quality and potentially impacting sensitive processes.

This revised guide expands on the original version, offering a more comprehensive and expert-oriented approach:

Pre-Installation Considerations

- Environmental Conditions: Ensure the cleanroom is completely sealed during installation. Allow ample time (ideally 3 days) for the FFU to purge any residual dust and contaminants.

- Personnel Requirements: Emphasize the critical role of cleanroom attire and gloves to prevent contamination. Consider limiting the installation team to 4-6 individuals to minimize potential human error.

- HEPA Filter Handling: Clearly address the fragility of HEPA filters. Advise against dropping the filter or opening the package during transport. Strictly prohibit direct contact with the filter media.

See more: Conditions for Fan Filter Unit Installation in Cleanrooms

Installation Procedure

- Tools and Equipment: Provide a detailed list of necessary tools, including aluminum ladders, safety harnesses, and filter lifting aids. Encourage strict adherence to safety protocols while emphasizing the use of appropriate personal protective equipment (PPE).

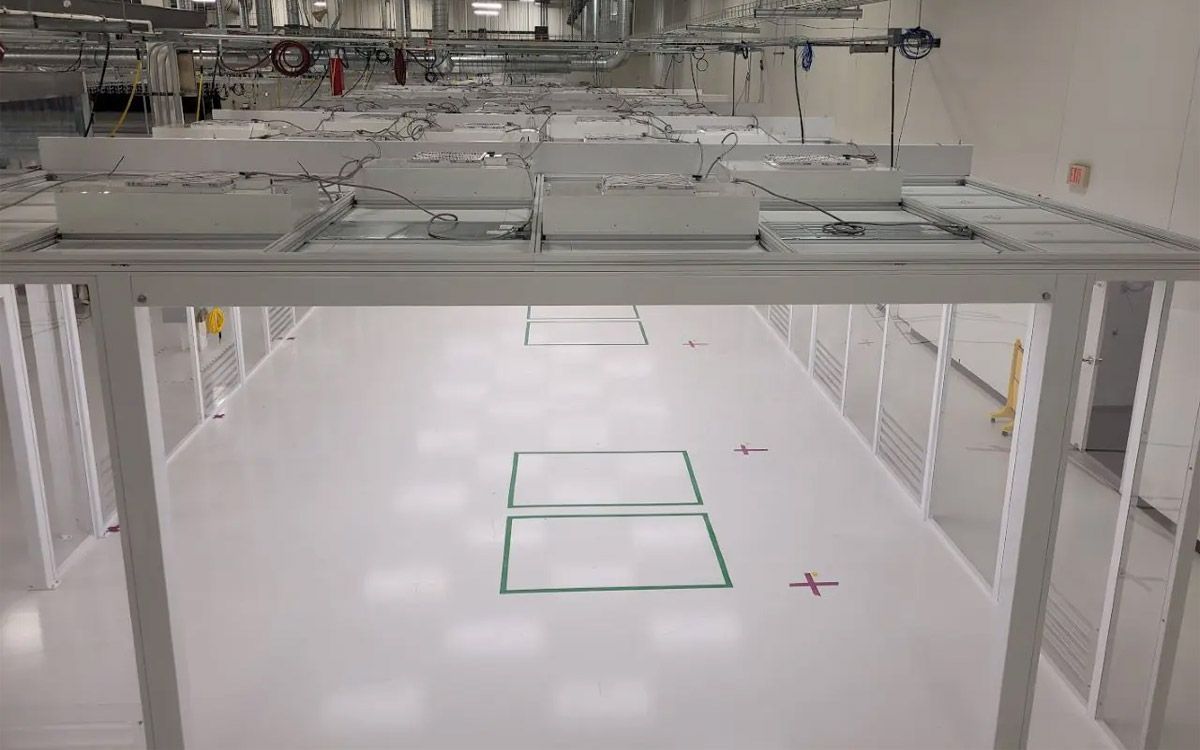

- Pre-staging: Clearly define designated areas for tool and FFU staging within the cleanroom. This helps maintain organization and minimize contamination risks.

- Teamwork and Communication: Clearly assign roles and responsibilities within the installation team. Emphasize clear and concise communication throughout the process to ensure smooth coordination and error prevention.

See more: Fan Filter Unit Specifications

Step-by-Step Guide for Installation Fan Filter Unit

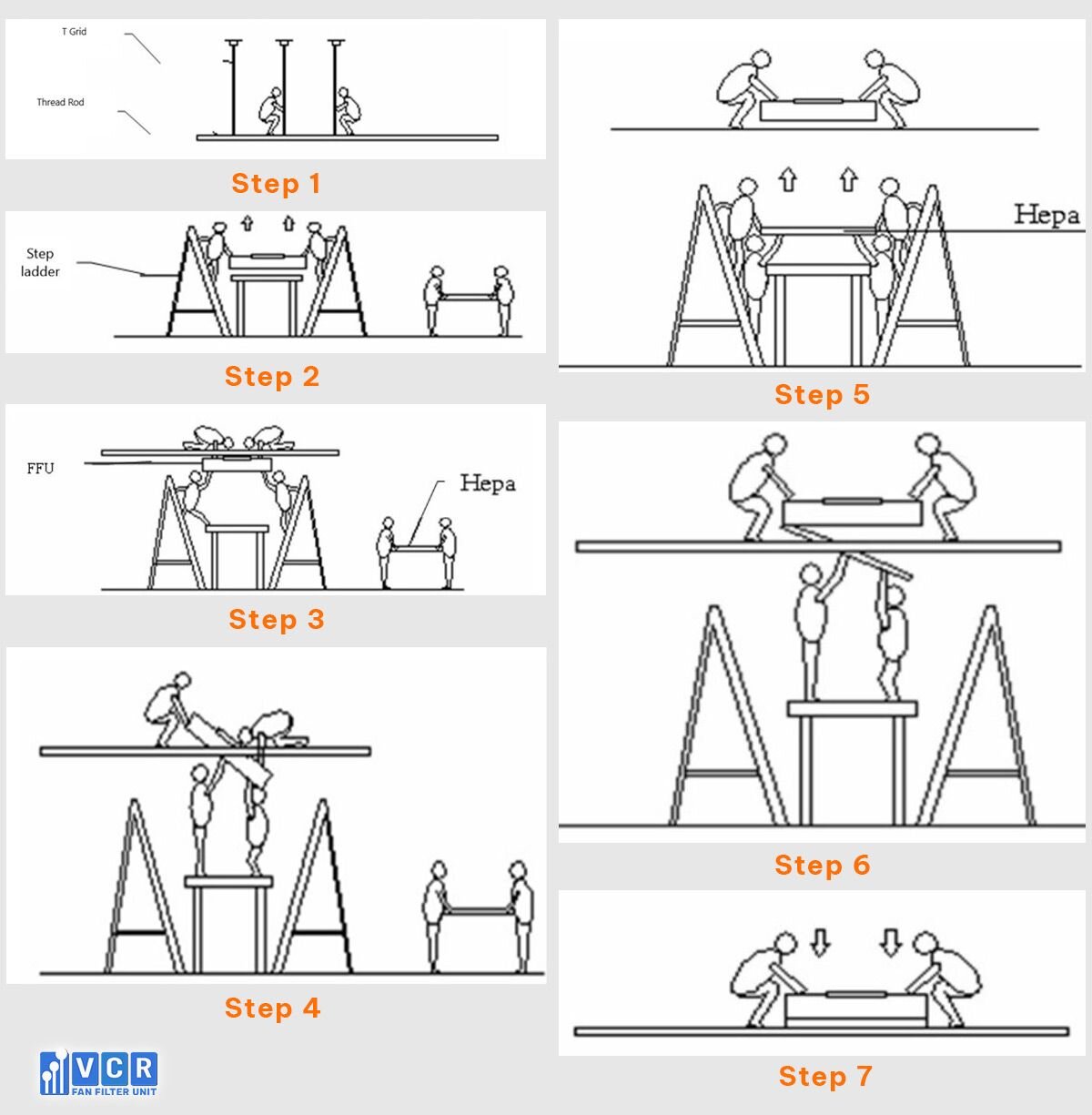

1. Ceiling Preparation: Two team members, equipped with proper PPE and safety harnesses, secure the ceiling frame and handrail screw bars. Double-check stability and adherence to safety regulations.

2. FFU and Filter Preparation: Two team members inside the cleanroom carefully place the FFU on a designated high table and prepare the HEPA filter for installation. Ensure the filter remains sealed and protected until the moment of installation.

3. Lifting and Positioning: Carefully lift the FFU onto the ceiling using designated lifting aids and proper technique. Maintain controlled movements and prioritize team safety.

4. HEPA Filter Installation: While tilting the FFU upwards, a team member inside the cleanroom swiftly installs the HEPA filter, meticulously aligning it with the designated slot and ensuring proper direction. Double-check for any gaps or misalignments.

5. Securing and Final Checks: Secure the FFU and filter firmly in place, following manufacturer instructions. Conduct a final visual inspection to ensure proper installation, filter integrity, and absence of contamination.

See more: FFU for Semiconductor cleanrooms

Additional Considerations

- Grounding and Electrical Connections: Address proper grounding procedures and highlight the importance of qualified electricians for electrical connections.

- Post-Installation Testing and Verification: Emphasize the importance of testing the FFU's performance, airflow patterns, and pressure differentials to ensure optimal operation and cleanroom integrity.

- Maintenance and Service: Briefly outline recommended maintenance procedures, filter replacement schedules, and the importance of adhering to manufacturer guidelines.

By following these comprehensive guidelines and seeking the expertise of qualified cleanroom professionals, you can ensure a successful and compliant FFU installation, contributing to a clean and controlled environment for your critical operations.

See more: FFU calculation for Cleanroom